Gas dynamics of combustion

Modern low-emission stationary gasturbines as they are used, e.g., in airplanes and industrial complexes, incline to fluctuating heat release and hence to a strong generation of noice. If the generated sound----interacts with resonant acoustic modes of the combustion chamber----- the so generated sound with the fuel chamber in resonance, it can come to the resonance katastanza what entails huge material charges. Around this effect as for example Helmholtz-Resonatoren, are often used in practice.

Modern low-emission stationary gasturbines as they are used, e.g., in airplanes and industrial complexes, incline to fluctuating heat release and hence to a strong generation of noice. If the generated sound----interacts with resonant acoustic modes of the combustion chamber----- the so generated sound with the fuel chamber in resonance, it can come to the resonance katastanza what entails huge material charges. Around this effect as for example Helmholtz-Resonatoren, are often used in practice.

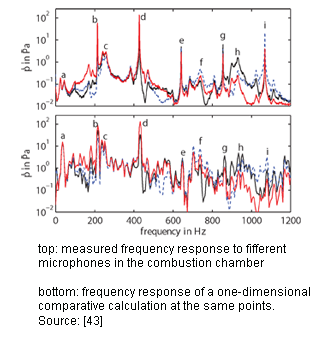

One of the main issues for the design of low-emission aero-engines, stationary gas turbines, industrial boilers and furnaces, and household burners is the noise associated with enclosed flames [1, 2]. Fluctuating heat release interacts with resonant acoustic modes of the combustion chamber and may lead to exceptionally high pressure oscillations. If certain phase relationships between the acoustic waves and the unsteady heat release prevail, the thermoacoustic system exhibits unstable modes, which grow in amplitude until limited by nonlinear mechanisms.

Mitigating these so-called thermoacoustic instabilities has been achieved by passive and active means.While passive means, such as Helmholtz resonators, are often applied in actual engines, reservations about the implementation of active control schemes are still prevalent. Computational modeling of thermoacoustic processes in combustion chambers in order to predict unstable operating regimes and to develop and test control methods is, therefore, highly desirable.